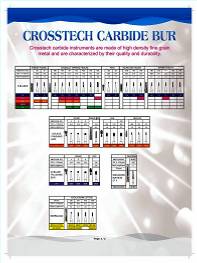

www.crosstechbur.com [email protected], Dental Burs by Crosstech Diamond Tools Co., Ltd.

Crosstech Diamond Tools Company Limited

has been approved for Sales and Distribution to the

Medical and Dental Universities/Colleges and Dentist within

the European Union Member Countries and the US

Domestic Market as per Certificates of European CE Mark, Canadian CMDCAS, Russian FDA, Korea KFDA, China, Japan and the US FDA Registration No. as attached below.

Hence, this is the Testimonial or Guarantee that

Crosstech Diamond Dental Burs has passed and are

in accordance with Multi International Standards.

Why Should Distributors or Dentist buy Crosstech Diamond Dental Burs ?

Crosstech Diamond Tools Co., Ltd. acquired the latest Technological Diamond Bonding Process and is a Multi International FDA Certified Manufacturer of High Precision Medical Products Class IIa Dental Diamond Burs. Hence, you can be assured that Crosstech Diamond Dental Burs are advanced Technological Products. Soon, Crosstech Diamond Dental Burs will be on most Dentist hand-piece and it is the only Bur product that Dentist will sought from Distributors and Dealers of Diamond Dental Burs in their area. Most importnt of all, check out this excellent One-Price Burs and one would be assured of its superb value over many other big brand names with its super high quality too.

How would Crosstech Diamond Dental Burs' quality against price ?

Crosstech Diamond Tools Co., Ltd. bought the Latest Diamond Bonding Patent Rights from a Western University Professor and combine it with an Eastern University Professor's ability to convert Theory into Practical Bulk Commercial Diamond Bonding and Plating in large quantities, by using moulds that could produce hundreds Burs, thus lowering the cost in production, in contrast to conventional Diamond Bonding and Plating process, by European and Japanese manufacturers, using the One-Piece by One Piece process, even in today's Technology Age.

Crosstech Diamond Dental Burs are sharper, and last much more longer than other brands of Diamond Burs, even up to Ten (10) times longer than Disposable Diamond Burs, saving Dentist time and money with great satisfaction. Crosstech Diamond Dental Burs vouch for its Product Quality with Full Money Back Guarantee or 300% Product Replacement.

Crosstech Diamond Dental Burs are priced much lower than most European and US Brands, and comparatively lower or cheaper in price than the Japanese Brands that are the major Dental Diamond Burs consumed with over 70% Market Share. Surprisingly it is at Disposable Diamond Burs Price, just One-Price for all Shapes and Sizes.

Is it safe and efficient to use Crosstech Diamond Dental Burs ?

Crosstech Diamond Dental Burs have evenly Multi-Layered Diamond grits over the upper stainless steel shank and with the Nickel plating coated layer, prevents any Vibrational Trauma during Surgical use. Crosstech Diamond Dental Burs ensures superb cutting and polishing efficiency, creating a neat, smooth and calibrated cut surface on all new repaired tooth..

What are the Test Certificates and Approval Authorities appraised Crosstech Diamond Dental Burs ?

Crosstech Diamond Dental Burs are exported to more than 64 Countries around the world, with each country's FDA permission to import and for free sales within the country, with approved Certificates of CE Mark, ISO 13485:2003, ISO 9001:2008, Canadian CMDCAS 13485:2003, and test on Cytotoxicity, Skin Irritation and Skin Sensitisation are performed and are passed by Crosstech Diamond Dental Burs.

One-Price Policy. No hassle in stock and cost problem.

Crosstech Diamond Dental Burs offers one-price policy for the full range of Diamond Dental Burs, be it in Standards, Coarse, Super Coarse, Fine or Super Fine or be it in round, flat-end, flame or inverted cone etc. Hence, managing your stock and costing is very easy and profits from costing is within finger-reach.

No more hesitation. This is your best choice and best Bur with best price available in market.

Browsing through till now, are you still not convinced yet? You have associated and used in the Dental market many brands already. No harm trying Crosstech Diamond Dental Burs out to see the difference or are Crosstech Diamond Dental Burs just blowing their loud horn too loud?

For the durability, safety and price-wise (Neither European or US nor Japanese prices), you need not think twice or pursue further elsewhere. Just contact us at email : [email protected]

Crosstech Dental Diamond Burs

The Harmonized System HS Code for Dental Diamond Tools (Burs), Surgical Tools etc. for the International Custom Import Tariff Harmonizes System Code starts with HS 9018.......... and varies from country to countries with HS 9018.4100, HS 9018.4990 etc.

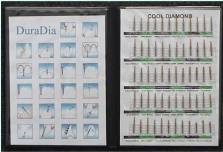

Pouch Folder Large with 261 Burs

Crosstech Pouch Folders for the Sales Team

The Manufacturing Criteria that Determine the Quality of a Super Diamond Bur.

There are several Important Criteria that determine the quality of a Superior Diamond Bur during the

manufacturing process as follows;

1) The Best Optimum Electrolyte will determine the quality of a Diamond Bur. Different factories

will have its

own recipe' of different chemical Electrolyte for manufacturing. This electrolyte that comprised of

several mineral chemcals (the purity and Ph quality water used is most important), will be part

utilized and partly consumed or vaporized during the Diamond Bur plating from hour to hour, and

from week to week and so on etc. Crosstech has acquired the latest chemical electrolyte process

for electroplating Diamond Burs from a Western University and perfected by a Eastern University

Professor.

To most manufacturing factories, it will change this chemical electrolyte in a six (6) months cycle.

Hence, the quality of the Diamond Burs in the first week, first month, Second month, 3rd month

and so on, will be different and will be stronly affected from bad to worst quality, as the electrolyte

deteriorate at the later period.

This is similar to the Photo Pictures Developing where the shop will change the chemical developer

only after hundreds of pictures, whereby the last batch of pictures are off natural colors due to the

weakening and expiring of the chemical developer. Until the shop decide to change to a fresh

chemical developer, or replenish additonal chemical developer, the quality of pictures developed will

be just becoming worst to more worst.

However, Crosstech has its own Technical Knowhow to determine the quality of the Chemical

Electrolyte every 24 hours and by weekly, partial Chemical Electrolyte are added to replenish the

part utilized Electrolyte to its optimum freshness, wherby it is always, having it best optimum

Electrolyte for Electro Diamond plating.

2) The Micro Ampheres Electricity that feed the Stainless Steel Burs in the Electrolyte must be

super accurate.

A slight fluctuation of the electrical current, do determine the quality of the diamond plating or over

burnt them. Crosstech has double stabalized its Factory electricity and has its special stable micro

ampheres meter feeders to Crosstech Patent Right Molds with hundred burs, and do adjusting its

micro amphere only suitable for each size of Diamond Bur with different Diamond head (Stainles

Steel) sizes.

3) The Quality of Diamond Powder do determine the sharpness and abrasive cutting power of a

Diamond Bur.

In general term, natural diamond powder has better abrasiveness than the synthetic diamond

powder, as explained in the Home page. Crosstech uses only the top quality natural diamond

powder with smaller amount of synthetic diamond powder from De Beers. Hence, Crosstech

Diamond Burs are always more abrasive.

4) The Quality of Stainless Steel assures the toughness in the high speed usage from any breakage

and bending trauma during surgical operation. The are three (3) types of quality Stainless Steel that

Crosstech uses in its Diamond Burs.

a) SUS 313 for normal Standard, Coarse, Fine, Super Fine and Super Coarse FG Diamond

Burs

b) SUS 314 for the short shank Standard, Coarse, Fine, Super Fineand Super Coarse FG

Diamond Burs

c) SUS 416 are under heat treatment for diamond head size smaller than 1 mm size to prevent

any snapping or breakage during surgical operation. It is more tough and can be bent over 150

degrees like a fishing hook..

Do NOT Trust what we have promoted so far, email us for sample to test out the Quality.

Crosstech Diamond Tools Co., Ltd. bought the Latest Diamond Bonding

Patent Rights from a Western Swiss University Professor and combine them with an Eastern Chinghua University Professor's ability to convert Theory into Practical Commercial Bulk Diamond Bonding and Nickel Plating in large quantities by using moulds that could produce hundreds Burs with stable electric Amphere, thus lowering the cost in production, in contrast to conventional Diamond Bonding and Plating process

by European and Japanese manufacturers, that are using the One-Piece by One-Piece process even in today's Technology Age. In addition, the slow swirling Electrolyte solvent is check and tested weekly, and adding any deficient electrolyte chemical nutrients, thus maintaining the most optimum

electrolyte solution for most efficient Diamond bonding.

Crosstech manufacture more than 3,200 types of shapes and sizes of Dental Diamond Burs.

In conventional piece by piece dangling into electrolyte Diamond plating, there will be Positive electric Amphere current that repel among dangling burs side by side, thus electrolyte plated diamond burs has uneven grit-diamond bonded, i.e. thickness and quantities of Diamond grits adhere to steel bur, due to repellent Amphere current, like the same pole repellent of magnet (North repel North pole or South repel South Pole etc.). Thus conventional European and Japanese Diamond burs are not as efficiently produced.

New Bridging Carbide Burs.

Super efficient Good Quality

Crosstech Diamond Tools Co., Ltd.

Room 508 Rama Jewelry Building

No. 987 Silom Road, Bangrak

Bangkok 10500, Thailand